Our Company

Owner Ben Bredo brings 25 years of industry experience to Valley Powder Coatings.

Who we are

Who we are

Valley Powder Coatings is a leading provider of high-quality powder coating service to manufacturers in Winnipeg and surrounding areas. Our commitment to a superior level of customer service, combined with our high standards of product quality, enables us to quickly, consistently and expertly deliver the highest quality finishing on your manufactured products.

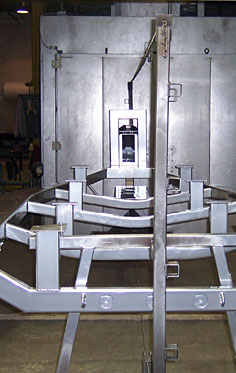

Centrally located at 15A Bury Street, our state-of-the-art, 13,000 square foot facility is found in the heart of Winnipeg’s manufacturing district. Our facility is also ISO certified and we are members of both the Canadian Paint & Coatings Association and the American Coating Association.

Owner Ben Bredo brings 25 years of industry experience to Valley Powder Coatings, and leads the day-to-day business by managing the front-office details, taking care of marketing and sales for the company, and overseeing the production operations.

Ben began his career with Quality Custom Coating, and was a project manager for 11 years with J R Stephenson Manufacturing Ltd., working primarily on their military contract with the US company General Dynamic. He spent his last two years with J R Stephenson as Sales Manager for the Mechanical Division before becoming the Marketing and Operations Manager at Quick Coatings Ltd., and following that, owner of Valley Powder Coatings.

Our history

Our history

Valley Powder Coatings Ltd. began almost two decades ago in Winkler, Manitoba by Pete and Brenda Dyck. Initially, it was a finishing service centre for Carte International Inc., who had one of its two production facilities located next door. Upon Pete and Brenda’s retirement, and Carte’s movement of all production to its Winnipeg facility, Valley Powder Coatings moved to its current location in Winnipeg to continue providing reliable service to Carte, while also expanding the business to new clients.

How we operate

At Valley Powder Coating, superior attention and care is given to every product, by way of our experienced technicians, thorough staff training and high-quality equipment processes.

Once your order is received, and the parts to be finished arrive at the shipping door, a work order is written up on the system, and the parts are tagged with the job specifications that follow it through every step in our process.

In the facility, parts first move through a five-stage preparation treatment dipping process, which includes an alkaline cleaner, a rinse, a phosphate, a second rinse and then a sealer. After preparation, the parts are sent to the powder booth for the coating application, followed by baking, cooling, and finally, packaging for shipment back to our customer.

We guarantee a 3–5 day turnaround on parts coated at our facility, in addition to 100% satisfaction with your finished product.

More about powder coating

The powder coating industry is tied directly to the manufacturing sector, as it is essentially the finishing process for many different types of manufactured metal parts, including appliances, hardware and car and bike parts. Powder coating involves the application of a free-flowing, dry powder onto manufactured parts, which when heated, fuses into a hard, protective layer.

The powder coating industry has grown steadily over the past number of years due to its cost-effectiveness, durability and environmental safety (no VOCs) compared to liquid-coating finishes.

Learn more about our powder coating process